Products

- Push In Terminal Block

- Spring Terminal Block

- Spring Clamp Terminal Block

- Electrical Terminal Block

- Screw Terminal Block

- Screw Connection Terminal Block

- Hand Crimp Tools

- Din Rail 35mm

- Terminal Bus Bar

- Terminal Block Relay

- Power Distribution Terminal

- Wire End Ferrules

- Push In Wire Connectors

- Plug Socket Waterproof Connector

- Waterproof Electrical Connectors

- Electrical Cabinet Air Filter

- Distribution Block

- Aluminum High-current Terminal Blocks

Wire Connector with Spring Terminal

Place of Origin: China

Brand Name: WONKEDQ

Certification: CE/RoHS/CQC/ISO 9001

Model Number: JST 10

Packaging Details: Box

Delivery Time: 2-7 days

Payment Terms: CE/RoHS/CQC/ISO 9001

Model:JST 10

Send Inquiry

Product Description

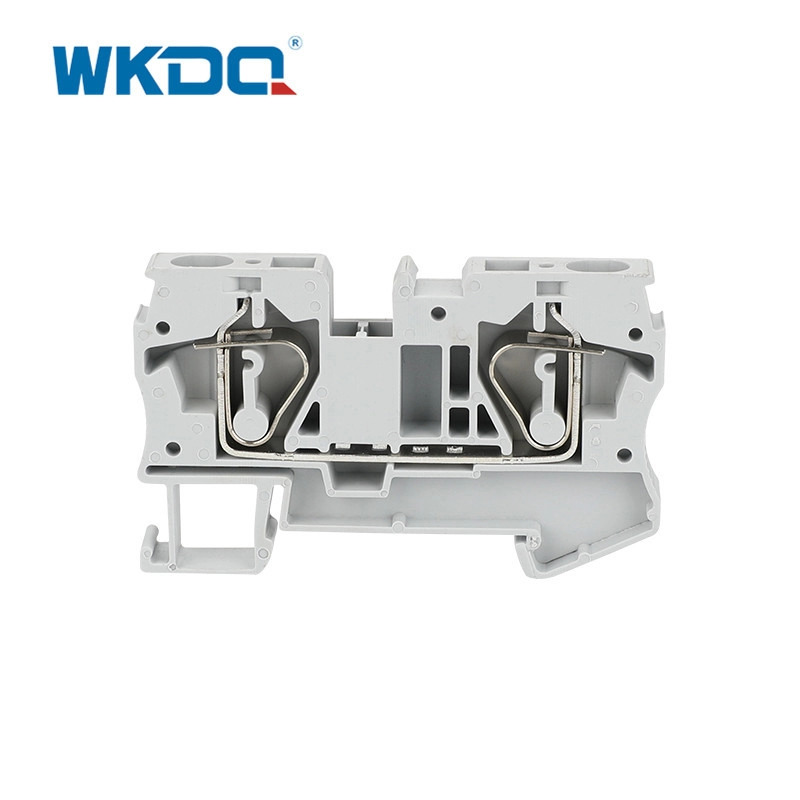

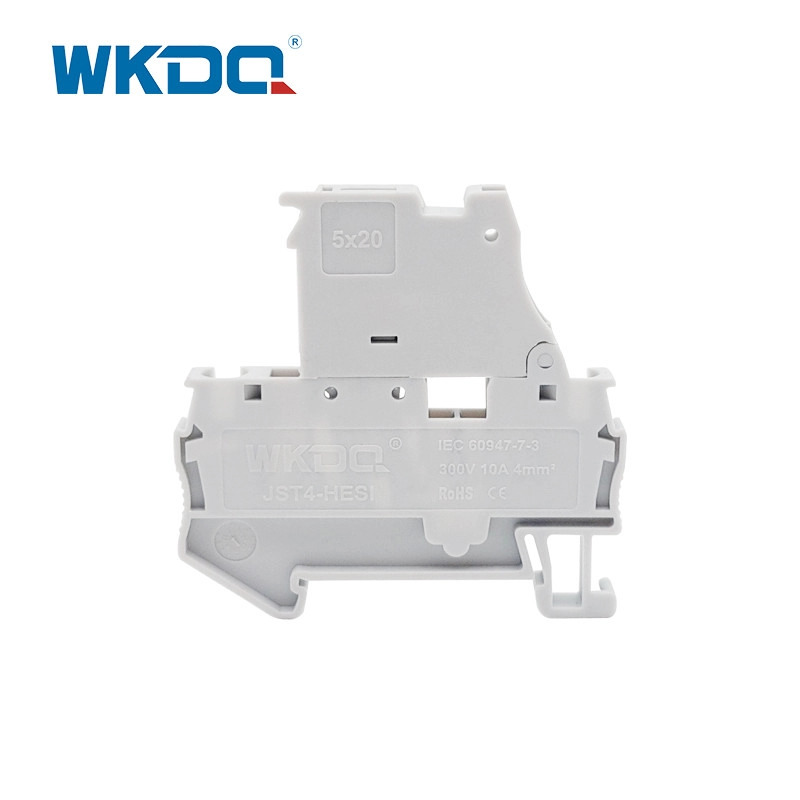

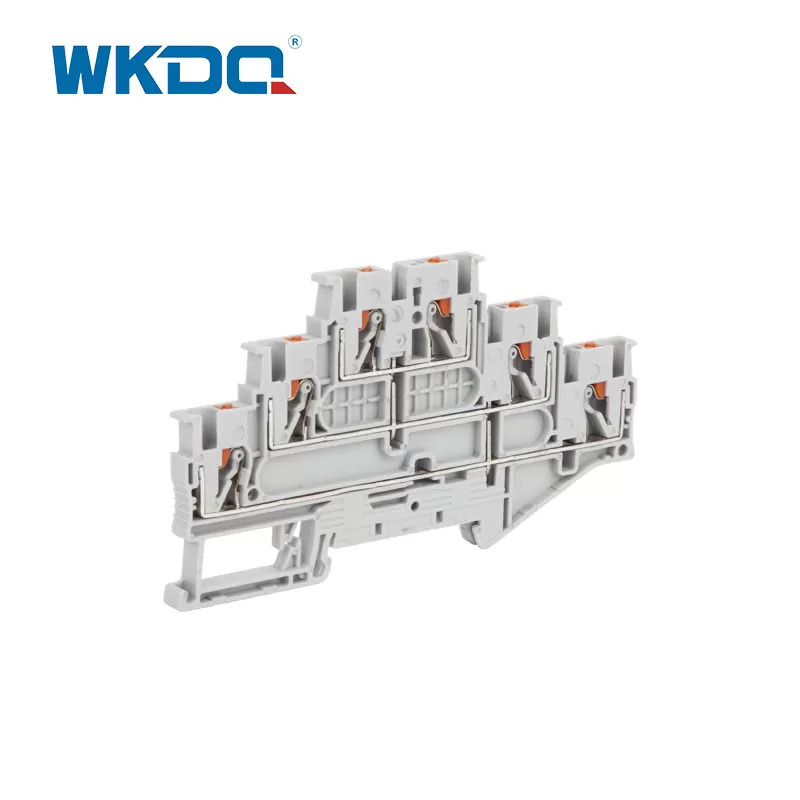

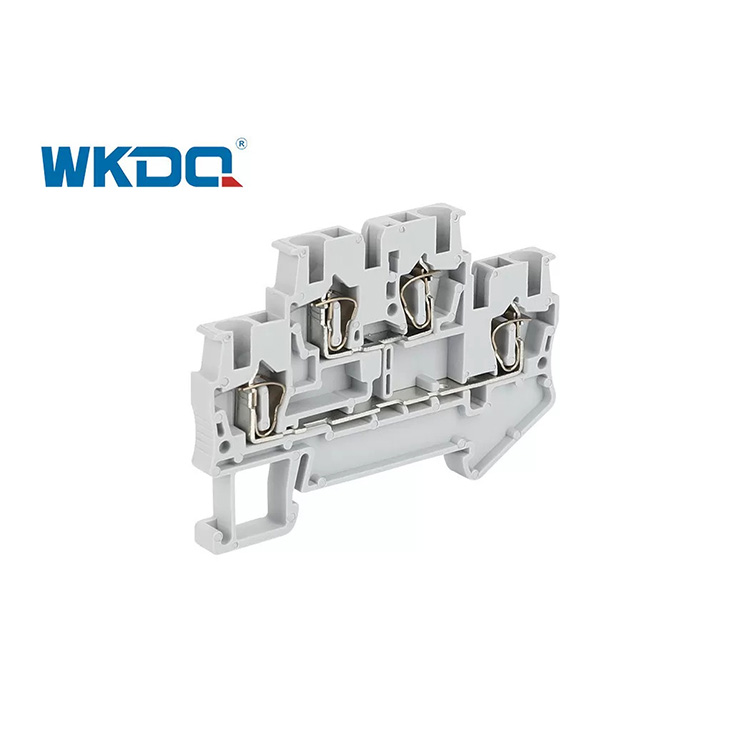

The spring cage terminal block combines a compact design (15% space-saving) with tool-free, screwless installation for

efficient wiring. Featuring nickel-plated copper contacts with stainless steel springs, it ensures corrosion resistance, low resistance, and gas-tight connections to eliminate signal loss. The PA66 nylon housing, IP20-rated protection, and DIN Rail NS35 compatibility suit harsh industrial environments, while integrated bridge plates and anti-misalignment markings boost reliability and enable 30% faster installation.

| Model Number | JST 10 |

| Color | Grey, Blue, other color can be customized |

| Length/Height/Wide (mm) | 71.5/49.5/10.2 |

| Connection method | Spring-cage connection |

| Material | Nylon PA66 |

| Rated Voltage/Current | 800V/65A |

| Cross section, solid/soft Cable | 0.5-16mm² / 0.5-10 mm² |

| Conductor Size | 16-6 AWG |

| Mounting Type | NS 35/7.5 |

| International Standard | IEC 60947-7-1 |

| Brand | Customized logo are supported |

| Packing method | 23.92g/pc, 40PCS/BOX, 800PCS/CTN |

| Certificates | CE/RoHS/CQC/ISO 9001 |

Hot Tags: Wire Connector with Spring Terminal, Manufacturers, Suppliers, China, Factory, Free Sample, In stock, Customized

Product Tag

Related Category

Push In Terminal Block

Spring Terminal Block

Spring Clamp Terminal Block

Electrical Terminal Block

Screw Terminal Block

Screw Connection Terminal Block

Hand Crimp Tools

Din Rail 35mm

Terminal Bus Bar

Terminal Block Relay

Power Distribution Terminal

Wire End Ferrules

Push In Wire Connectors

Plug Socket Waterproof Connector

Waterproof Electrical Connectors

Electrical Cabinet Air Filter

Distribution Block

Aluminum High-current Terminal Blocks

Send Inquiry

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.

Related Products