- Push In Terminal Block

- Spring Terminal Block

- Spring Clamp Terminal Block

- Electrical Terminal Block

- Screw Terminal Block

- Screw Connection Terminal Block

- Hand Crimp Tools

- Din Rail 35mm

- Terminal Bus Bar

- Terminal Block Relay

- Power Distribution Terminal

- Wire End Ferrules

- Push In Wire Connectors

- Plug Socket Waterproof Connector

- Waterproof Electrical Connectors

- Electrical Cabinet Air Filter

- Distribution Block

- Aluminum High-current Terminal Blocks

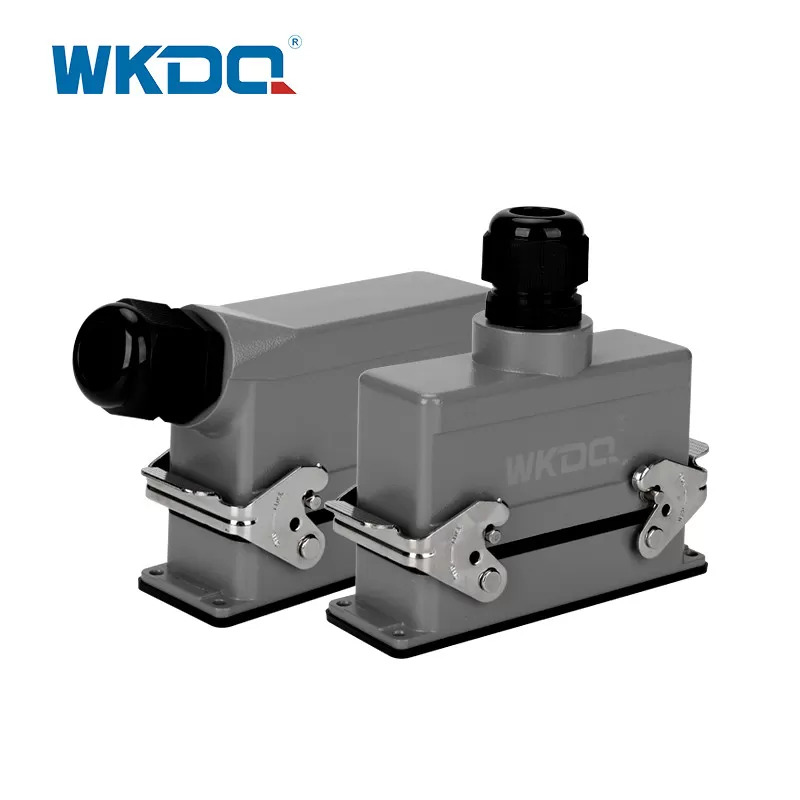

WHE06C Heavy Duty Cable Connectors Silver Plated

The WKDQ WHE06C Heavy Duty Cable Connectors Silver Plated typically refer to connectors designed for demanding applications that require high conductivity, durability, and resistance to corrosion.

Model:WHE06C

Send Inquiry

The WKDQA WHE06C Heavy Duty Cable Connectors Silver Plated are designed to provide robust and reliable electrical connections in demanding applications. The silver plating serves several purposes:

Enhanced Conductivity: Silver is an excellent conductor of electricity. By silver plating the connectors, the electrical conductivity is improved, ensuring efficient transmission of electrical signals or power.

Corrosion Resistance: Silver is known for its resistance to oxidation and corrosion. The silver plating acts as a protective layer, preventing the connectors from corroding over time, especially in harsh environments or when exposed to moisture or chemicals.

Low Contact Resistance: The silver plating helps reduce contact resistance between the connectors. Lower contact resistance means less energy is wasted as heat, ensuring better electrical performance and minimizing voltage drop.

High Temperature Resistance: Silver has good thermal conductivity and high melting point. When used in heavy-duty applications where higher temperatures may be present, the silver plating helps the connectors maintain their integrity and electrical performance.

These features make heavy-duty cable connectors with silver plating suitable for various industries, such as power generation and distribution, industrial machinery, aerospace, automotive, and telecommunications, where reliable and efficient electrical connections are crucial. However, it's essential to consider specific product specifications and guidelines provided by the manufacturer to ensure compatibility and optimal performance in your specific application.

TECHNICAL PARAMETERS

| No. | PART NO. | Entry Side | Number of contact |

A (mm) |

B (mm) |

C (mm) | D (mm) | E (mm) | F (mm) | G (mm) |

|

Heavy-duty connector Voltage/Current: 500V/16A Surface: Sliver-plated Contact resistance: ≤1m ΩCross section: 1.0-2.5mm² (AWG 18-14) Tightening torque: 0.5Nm Stripping lenngth: 7mm |

|

|||||||||

| 1 | WHE06C | Side entry | 6 | 80.0 | 43.0 | 52.2 | 35.0 | 32.0 | 70.0 | 4.3 |

| 2 | WHE06D | Top entry | 6 | 80.0 | 43.0 | 52.2 | 35.0 | 32.0 | 70.0 | 4.3 |

| 3 | WHE10C | Side entry | 10 | 93.0 | 43.0 | 65.2 | 35.0 | 32.0 | 83.0 | 4.3 |

| 4 | WHE10D | Top entry | 10 | 93.0 | 43.0 | 65.2 | 35.0 | 32.0 | 83.0 | 4.3 |

| 5 | WHE16C | Side entry | 16 | 113.0 | 43.0 | 85.5 | 35.0 | 32.0 | 103.0 | 4.3 |

| 6 | WHE16D | Top entry | 16 | 113.0 | 43.0 | 85.5 | 35.0 | 32.0 | 103.0 | 4.3 |

| 7 | WHE24C | Side entry | 24 | 140.0 | 43.0 | 112.2 | 35.0 | 32.0 | 130.0 | 4.3 |

| 8 | WHE24D | Top entry | 24 | 140.0 | 43.0 | 112.2 | 35.0 | 32.0 | 130.0 | 4.3 |

| 9 | WHE32C | Side entry | 32 | 113.0 | 80.5 | 86.0 | 73.0 | 60.0 | 103.0 | 4.5 |

| 10 | WHE32D | Top entry | 32 | 113.0 | 80.5 | 86.0 | 73.0 | 60.0 | 103.0 | 4.5 |

| 11 | WHE48C | Side entry | 48 | 140.0 | 80.5 | 113.0 | 73.0 | 60.0 | 130.0 | 4.5 |

| 12 | WH48D | Top entry | 48 | 140.0 | 80.5 | 113.0 | 73.0 | 60.0 | 130.0 | 4.5 |