- Push In Terminal Block

- Spring Terminal Block

- Spring Clamp Terminal Block

- Electrical Terminal Block

- Screw Terminal Block

- Screw Connection Terminal Block

- Hand Crimp Tools

- Din Rail 35mm

- Terminal Bus Bar

- Terminal Block Relay

- Power Distribution Terminal

- Wire End Ferrules

- Push In Wire Connectors

- Plug Socket Waterproof Connector

- Waterproof Electrical Connectors

- Electrical Cabinet Air Filter

- Distribution Block

- Aluminum High-current Terminal Blocks

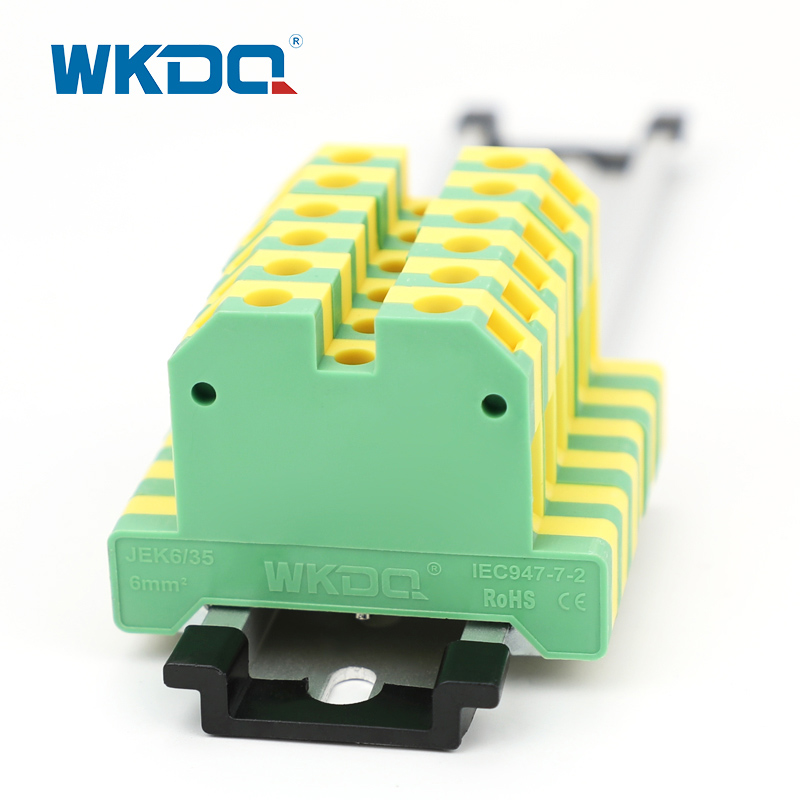

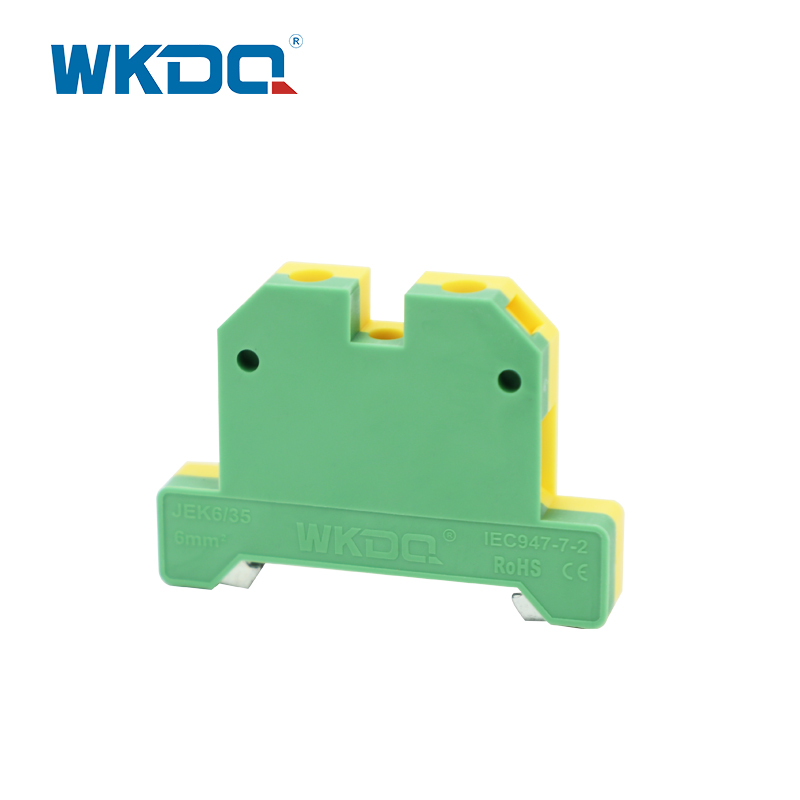

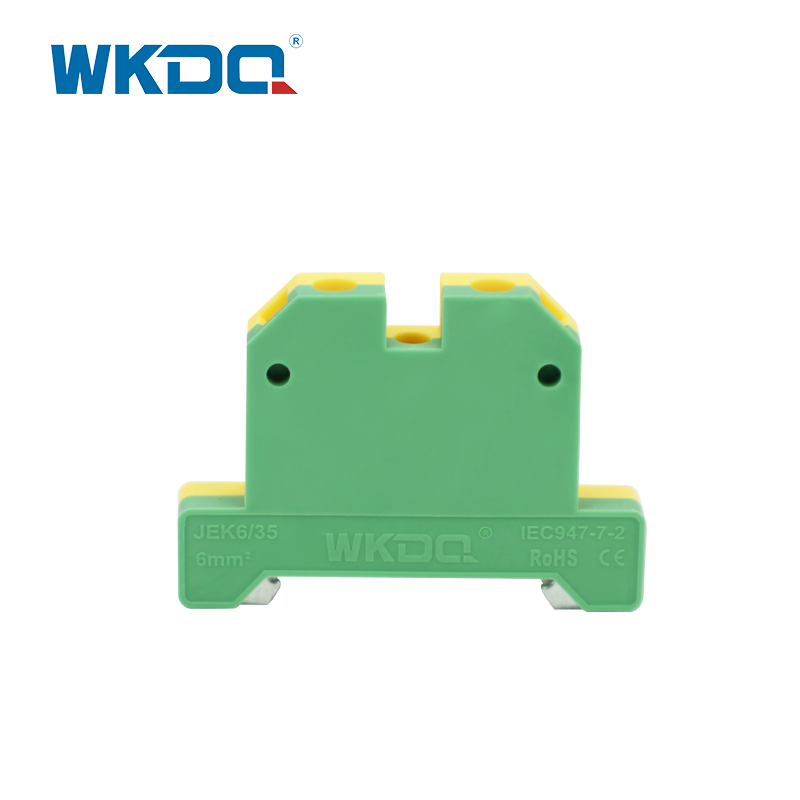

Screw Connection Terminal Block PE

Place of Origin: China

Brand Name: WONKEDQ,WKDQ

Certification: CE, RoHs, CQC,etc

Model Number: JEK 6/35

Packaging Details: Box

Delivery Time: 2-7 days

Payment Terms: T/T, Paypal, Western Union, etc

Send Inquiry

|

Model Number: |

JEK 6/35 |

Length: |

57.5 |

|

Height: |

41 |

Wide: |

8 |

|

Rated Cross Section: |

6 Mm² |

Packing Detail: |

24.86g/pc, 40PCS/BOX, 720PCS/CTN |

|

High Light: |

electrical screw terminal block connector , screw down wire connector |

||

The grounding terminal blocks are designed to securely and electrically connect wires to the DIN rail using a conducting clamping foot, effectively utilizing the DIN rail as a ground bus bar.

Key Features:

Easy to operate: The grounding terminal blocks are user-friendly and easy to operate, simplifying the installation process.

Steady structure: These terminal blocks have a robust and stable structure, ensuring durability and reliability in various applications.

Vibration-proof: The grounding terminal blocks offer excellent vibration-proof protection, preventing loosening and maintaining secure electrical connections.

Safe and stable performance: These terminal blocks provide safe and stable performance, ensuring reliable grounding and system operation.

Shock resistance & Corrosion resistance: The terminal blocks are designed to withstand shocks and are resistant to corrosion, ensuring long-lasting performance and reliability.

Made from safe and high-quality materials: The grounding terminal blocks are constructed using safe and high-quality materials, guaranteeing electrical safety and product longevity.

Simple and convenient installation: These terminal blocks are designed for simple and convenient installation, saving time and effort.

Perfectly suitable for electrical machine control systems: The grounding terminal blocks are specifically designed to meet the requirements of electrical machine control systems, ensuring compatibility and optimal performance.

Excellent vibration-proof protection: These terminal blocks provide excellent protection against vibrations, ensuring secure and reliable electrical connections.

Maintenance-free conductor connection: The grounding terminal blocks offer a maintenance-free connection for conductors, reducing the need for regular maintenance and ensuring long-term reliability.

Protective insulation: The Ground Terminal Blocks offer protective insulation, providing confidence in the safety and security of your product.

Made from engineering antiflaming nylon PA66 with brass screw metal: The terminal blocks are made from high-quality engineering antiflaming nylon PA66 material with brass screw metal, ensuring both mechanical strength and electrical conductivity.

Green and yellow color: The grounding terminal blocks are molded in green and yellow, following international standards for ground circuits.

No need for an end stop: When a ground block is positioned at the end of a terminal block assembly, there is no need to use an end stop, simplifying the installation process.

Universal foot: These terminal blocks feature a universal foot design, allowing them to be easily snapped onto Terminal DIN Rails, ensuring secure and reliable mounting.

In summary, the grounding terminal blocks provide a reliable and efficient solution for securely connecting wires to the DIN rail, utilizing it as a ground bus bar. With their easy operation, steady structure, vibration-proof design, and safe performance, these terminal blocks ensure reliable grounding and system operation. Made from safe and high-quality materials, they offer durability, electrical safety, and corrosion resistance. The simple installation process, excellent vibration-proof protection, and maintenance-free conductor connection contribute to their efficiency and long-term reliability. These terminal blocks are perfectly suited for electrical machine control systems, providing confidence in the safety and security of your product.