- Push In Terminal Block

- Spring Terminal Block

- Spring Clamp Terminal Block

- Electrical Terminal Block

- Screw Terminal Block

- Screw Connection Terminal Block

- Hand Crimp Tools

- Din Rail 35mm

- Terminal Bus Bar

- Terminal Block Relay

- Power Distribution Terminal

- Wire End Ferrules

- Push In Wire Connectors

- Plug Socket Waterproof Connector

- Waterproof Electrical Connectors

- Electrical Cabinet Air Filter

- Distribution Block

- Aluminum High-current Terminal Blocks

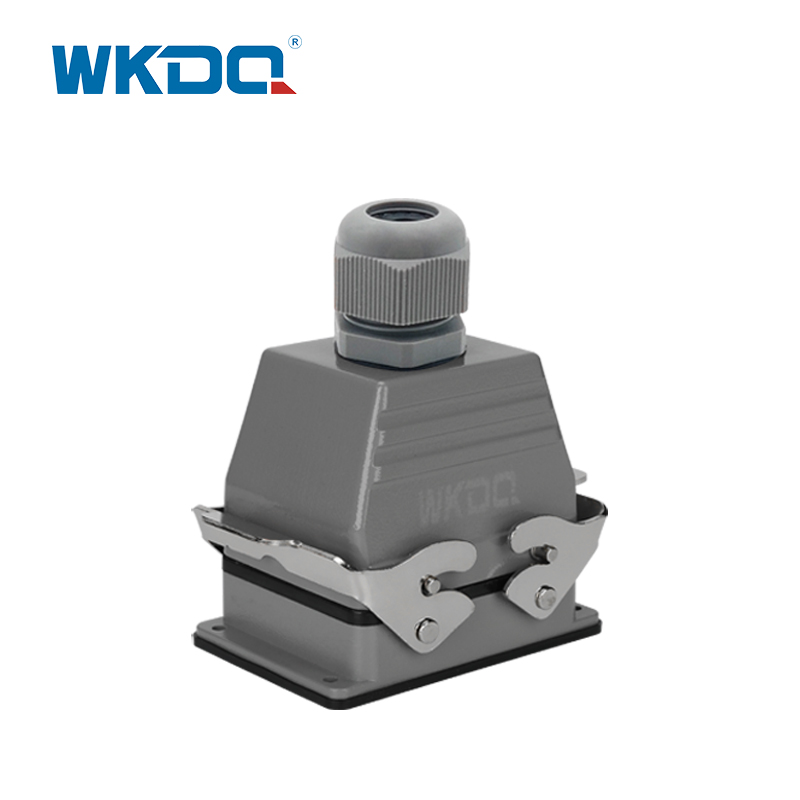

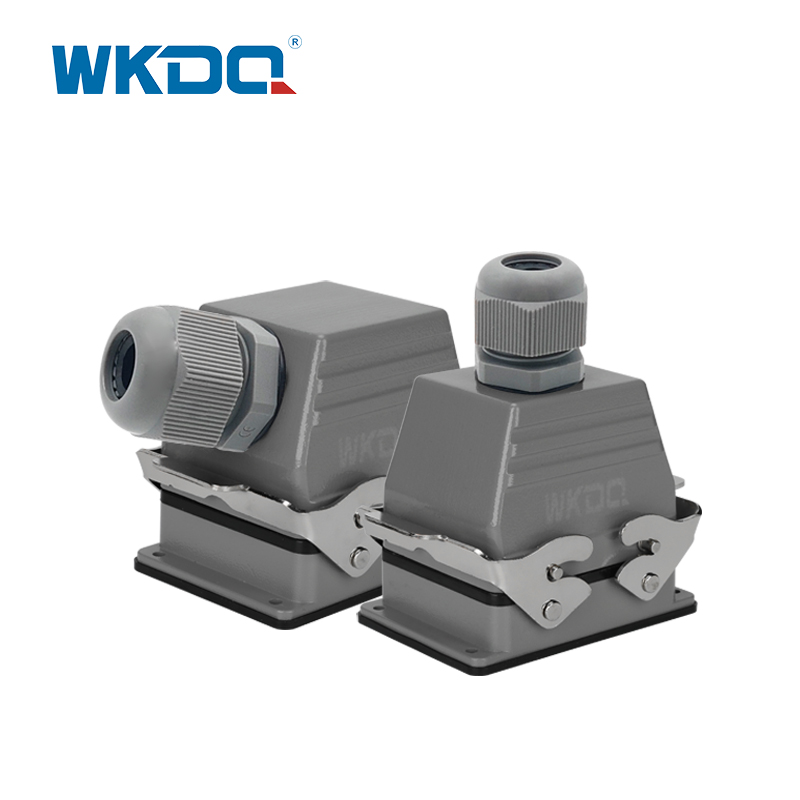

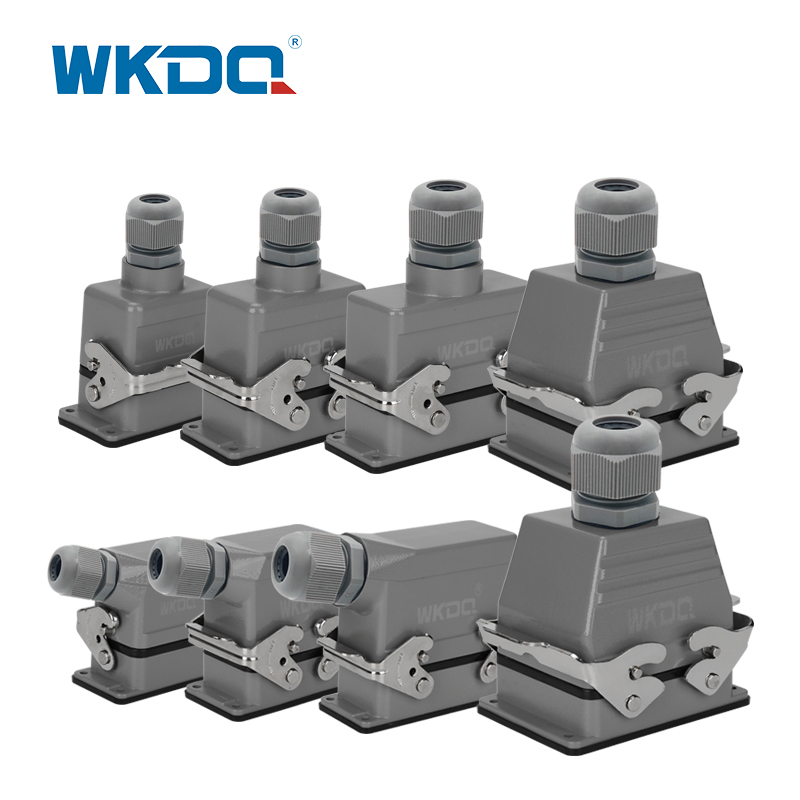

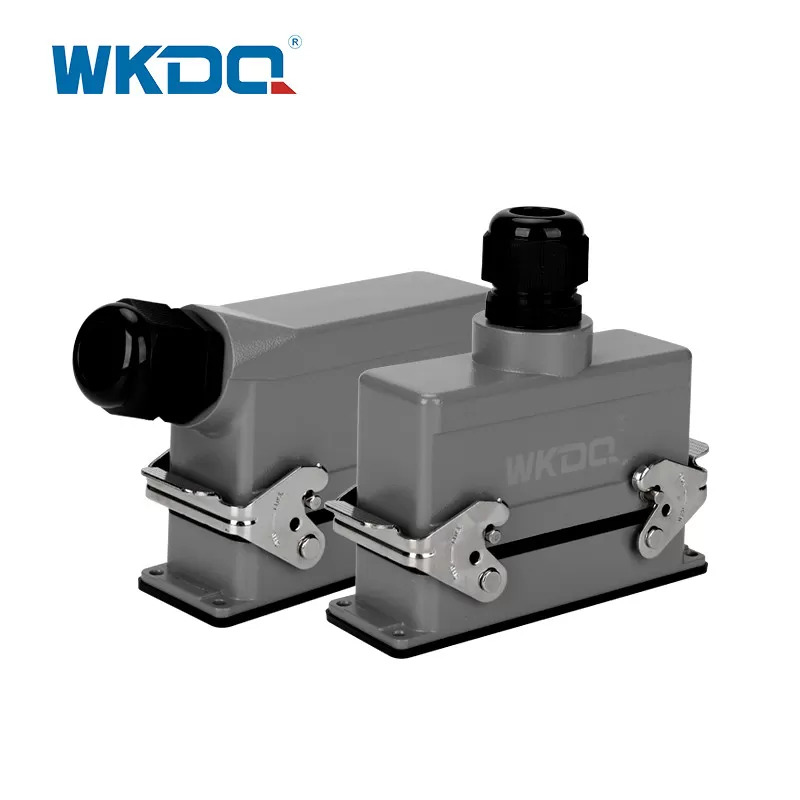

32 Pins High Current Connector Top Out

Place of Origin: China

Brand Name: WONKEDQ

Certification: CE/RoHS/CQC/ISO 9001

Model Number: WHE32D/P

Packaging Details: Box

Delivery Time: 2-7 days

Payment Terms: T/T, Paypal, Western Union, etc

Send Inquiry

The WKDQ WHE Series Anti-Corrosion IP65

Waterproof Electrical Connectors are meticulously engineered to provide

excellent protection against corrosion and ensure a high level of ingress

protection against dust and water. Let's explore their key features:

Anti-Corrosion Properties: These connectors

are designed with materials and coatings that exhibit exceptional resistance to

corrosion. Corrosion can significantly impact the performance and reliability

of electrical connectors, particularly in environments with high humidity,

moisture, or exposure to chemicals. The anti-corrosion properties of these

connectors ensure long-lasting durability and reliable operation, even in

challenging conditions.

IP65 Rating: These connectors have an IP65

Ingress Protection rating, indicating their superior defense against solid

particles, such as dust, and protection against low-pressure water jets from

any direction. The "6" in the IP65 rating denotes the highest level

of dust-tight protection, while the "5" signifies protection against

low-pressure water jets. With this rating, these connectors offer comprehensive

protection against dust ingress and water exposure.

Waterproof Design: The connectors are

specifically designed with a waterproof feature to effectively prevent the

ingress of water, even when subjected to low-pressure water jets. This level of

waterproofing ensures their safe and reliable use in outdoor or damp

environments where protection against water ingress is crucial to maintain

electrical integrity and prevent damage.

The WKDQ WHE Series Anti-Corrosion IP65

Waterproof Electrical Connectors find extensive applications in various

industries, including outdoor lighting, marine equipment, industrial machinery,

and electrical systems exposed to demanding environments. They are particularly

valuable in settings where there is a risk of water exposure, dust

accumulation, or the presence of corrosive substances.

When selecting these connectors, it is

vital to consider specific application requirements such as connector size, pin

configuration, and adherence to the manufacturer's guidelines. This ensures

compatibility and enables the connectors to deliver optimal performance in your

specific application.